HDPE Granules and Grades

What is HDPE (high-density polyethylene)?

HDPE stands for High-Density Polyethylene. High-Density Polyethylene (HDPE), generally known as Polyethylene High-Density (PEHD), is a thermoplastic polymer created from the ethylene monomer.

HDPE (high-density polyethylene)

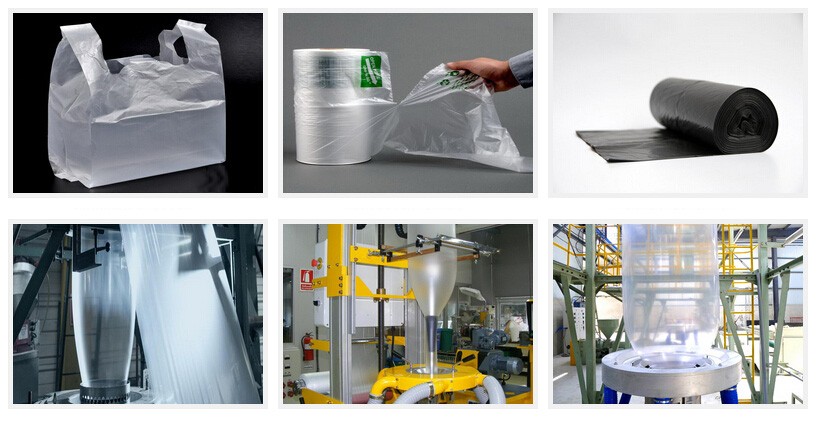

HDPE (high-density polyethylene) can be processed in a variety of ways such as , Blow Molding, Injection Molding, Blown film, Pipe Extrusion, HDPE granule are graded according to these processes and each process contains several grades. Our HDPE granules are categorized in these four major grades.

Blow molding is the forming of a hollow object by inflating or blowing a thermoplastic molten tube called a “parison” in the shape of a mold cavity. The process consists of extruding or “dropping” a parison on which female mold halves are closed. The female mold halves contain the shape of the product to be produced. Granules for blow molding process varies. For viewing blow molding grades, click on more info

Injection molding is a process in which a thermoplastic polymer is heated above its melting point, resulting in the conversion of the solid polymer to a molten fluid with a reasonably low viscosity. This melt is mechanically forced, injected, into a mold in the shape of the desired final object. HDPE Granules for this process varies. For viewing blow molding grades, click on more info

Blown films, also commonly known as tubular films, are created by extruding plastic through a tubular-shaped die and then stretched and blown with air to create a very thin-walled film. Polyethylene types such as LDPE, LLDPE and HDPE polymers are common resins that are used to create blown films. HDPE Granules for injection molding process varies. For viewing blow molding grades, click on more info

Pipe Extrusion Grades

A pipe extrusion line consists of different parts. An extruder converts raw plastic material into a continuous tubular melt by extrusion through an annular die. The molten pipe then proceeds through a sizing or calibration bench (which adjust its dimensions) to a cooling tank. HDPE Granules for pipe extrusion process varies. For viewing pipe extrusion grades, click on more info