Polymers widely used in making bottles

Polyethylene Terephthalate, which is one of the most widely used thermoplastic polymers in the world, is used to make all kinds of bottles. In the textile industry, this polymer is known as polyester. In the food and beverage packaging industry, it is referred to as PET or PET resin. In the past, another type called PET-P was used in the clothing industry, which has almost stopped being used today.

Polymers widely used in making bottles

Polyethylene terephthalate (PET) is a polymer that is used in most countries to produce polyester fibers (70 percent), bottle resin (22 percent), film (6 percent) and engineering polyester resins (2 percent), but in Iran this polymer It is mostly used to make all kinds of drinking bottles. Due to the high resistance of these bottles against breakage, temperature and gas penetration, low weight and cheap price compared to other packaging materials such as glass and metal, the production of plastic bottles from this material has found wide use.

Characteristics of granular pet

Granule PET is a suitable waterproofing agent. Granule PET is a safe, strong, light, flexible and non-toxic material that can be easily recycled. The presence of all these features in one product has attracted the attention of all people working in the field of packaging to this product. Among the features that have led to the use of this product in the packaging of food and beverages, we can mention its lightness, strength, preservation of health and freshness of the product, and the fact that it cannot be crushed. One of the main uses of this product is its use in mineral water and carbonated soft drinks.

Advantages and disadvantages of granule PET (polyethylene terephthalate)

These polymers are easily available and cheap.

PET polymers are resistant to moisture and organic substances, water and chemicals.

The ratio of their resistance to their weight is very high.

They are very transparent and unbreakable. (They don’t break like glass packages.)

Polyethylene tereflat is easily recyclable. PET plastic is one of the types of recycled plastics that are used to produce products such as containers, sleeping bag insulation, polyester fabrics and carpets, etc.

PET plastics are not biodegradable. This can be good or bad depending on their application.

PET polymer has lower thermal resistance than other polymers.

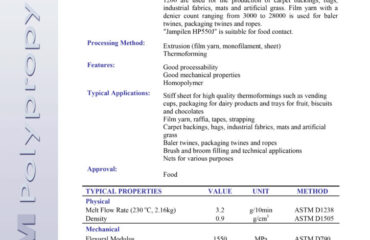

1- Polyethylene terephthalate BG781

Polyethylene terephthalate (BG781 (BG780S) is a bottle-grade polyethylene terephthalate (PET) produced during the process of continuous melt polymerization along with solid state polymerization. BG781 material has excellent transparency and gloss and very good toughness and is resistant to oxygen penetration And carbon dioxide is very resistant.Its applications are in oil and mineral water bottles and all kinds of small jars.

Feature Pat BG781

It has excellent transparency and gloss and very good toughness and is very resistant to the penetration of oxygen and carbon dioxide.

Application of PET BG781

Bottles of mineral water, edible oil

2- Polyethylene terephthalate BG825

Polyethylene terephthalate (BG825 (BG820N) is a bottle-grade polyethylene terephthalate (PET) produced during the process of continuous melt polymerization along with solid state polymerization. And carbon dioxide is very resistant.Its applications are in carbonated beverage bottles.

Feature Pat BG825

It has excellent transparency and gloss and very good toughness and is very resistant to the penetration of oxygen and carbon dioxide.

Application of PET BG825

Bottles of carbonated drinks

Conclusion

Polymer materials are widely used in the production of nylon and also in the production of disposable containers and bottles. In this article, we got to know the most commonly used grades in bottle making.